Results 61 to 80 of 128

Thread: Header Install

-

05-24-2010, 03:28 AM #61

-

05-24-2010, 03:07 PM #62

Mine was tight at the K-member and on that square piece but I didn't modify it. Sure, it was tight, but it fit- the square peice and the header are both fixed so they shouldn't rub, but the K shouldn't be an issue since the poly mounts won't let it move much. I'm keeping an eye on it to make sure that the pipe isn't rubbing the K, but so far so good.

-

05-30-2010, 01:36 PM #63

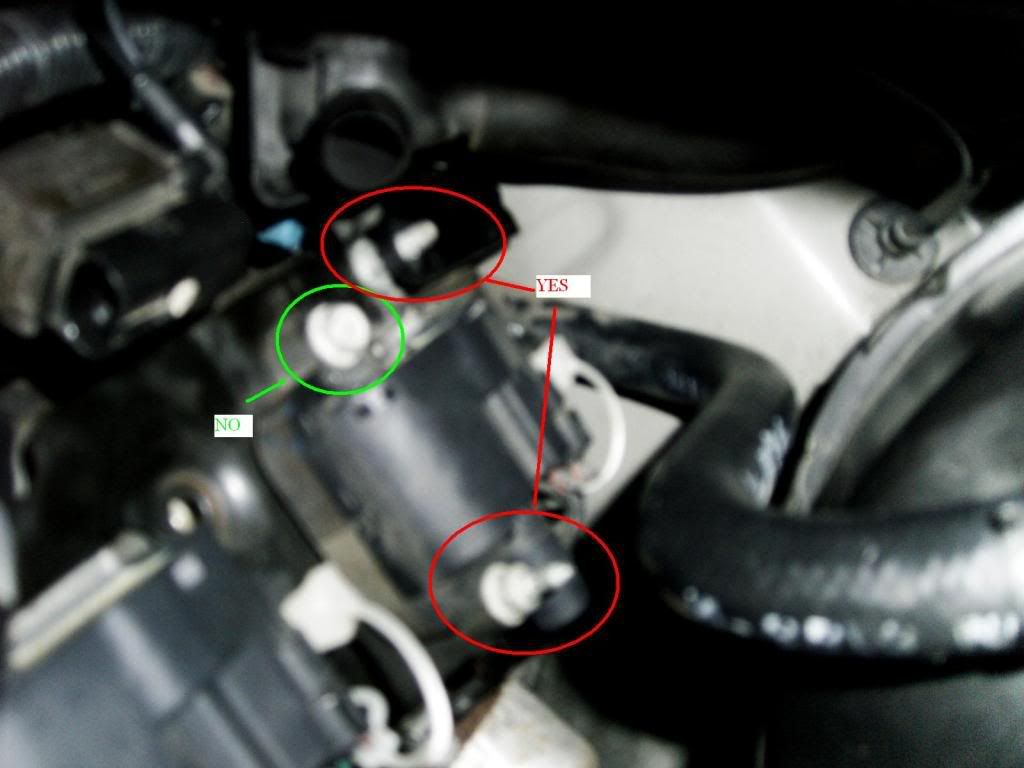

Okay... I unbolted the DS motor mount from the K-Member side and jacked up the motor for more clearance. I then tried to install the header and it still isn't sliding through. It still appears to be caught between the K-Member and block (machined lip where the oil filter is placed). Here is a pic of where the header is making contact with the K-Member and motor.

-

05-30-2010, 06:56 PM #64Senior Member

- Join Date

- Apr 2008

- Location

- Madison, WI

- Posts

- 7,006

1999 Formula WS6 M6-sold- 2001 Silverado Z71

I couldn't get my drivers side Kooks header in very easily either. I suspect if I had it up higher on a hoist I would have been able to twist it up in there better.

I had to remove the motor mount stand from the car, slide the header up in there, loosely hold it up there with one loosely threaded in bolt and then reinstall the motor mount stand.

-

05-30-2010, 06:57 PM #65

I ended up shaving the K a little. If I were you, start with the K- you've got over a 1/4 inch you can shave and smooth. Try that first. I wouldn't go about messing with machined lip at the oil filter. If it's hitting that lip, most likely your oil filter is going to hit as well and that'll never work.

-

07-28-2010, 08:48 AM #66Member

- Join Date

- Nov 2009

- Location

- Altoona and Downingtown, PA

- Posts

- 271

Black- 1998 Z28 and 67 Firebird

Hey! I just bought the race style pacesetter headers, and i'm taking out the EGR and AIR. Where do i get the block off plates for removing those?

-

07-28-2010, 09:07 AM #67

-

07-30-2010, 03:44 PM #68

-

09-05-2010, 06:22 PM #69

any 1 got tips on getting the y pipe bolts off the exhaust manifolds? i could not get them suckers off w/ an breaker bar or an impact wrench, sprayed em down with some break free, and even tried wd40.

-

09-05-2010, 06:27 PM #70Senior Member

- Join Date

- Apr 2008

- Location

- Madison, WI

- Posts

- 7,006

1999 Formula WS6 M6-sold- 2001 Silverado Z71

I believe I snapped more then half of mine when I did my removed my stock setup.

-

09-05-2010, 07:46 PM #71

Spray the bolts down with PB Blaster and let it soak. Mine came right off. If that doesn't work, get a torch and heat them up. If that doesn't work, cut the SOB's off- you don't need to reuse them anyway!

-

09-05-2010, 08:20 PM #72

-

11-04-2010, 12:05 PM #73

Also, i recommended this in my own how to install for OBX headers, after jacking the car up, soak em in PB blaster over night, then in the morning of, spray em again and then warm the car up for about 5 or ten minutes. the amount of tim eit would take for you to walk to you fridgeand get a beer or a cup of coffee then shut it off. the heat helps loosen the bolts a bit and makes for working on other parts easier. warm bolts are easier the stone cold ones

helped me. I only snapped off two on my cat to manifold bolts and accually used then bolt my y pipe to the Y-pipe mounting bracket

helped me. I only snapped off two on my cat to manifold bolts and accually used then bolt my y pipe to the Y-pipe mounting bracket

-

11-26-2010, 09:35 PM #74Junior Member

- Join Date

- Nov 2010

- Location

- kings bay

- Posts

- 12

blue- 99 firebird formula

when i did mine i slid them in from the top but i did it in a parking lot by my self.

-

12-16-2010, 09:51 PM #75**Te@M fBoDy**

- Join Date

- Nov 2010

- Location

- The Woodlands,Texas...N.O.

- Posts

- 1,016

Pewter Metallic- 2000 Pontiac Trans Am WS6

Nice write up we needed that info

-

01-13-2011, 12:19 PM #76

Dude this thread is extremely helpful. I am putting BBK LT headers on my car as soon as I get the last few small parts together. My question for you is about the EGR block off plate I see where they need to go is there any kind of plug I can put in the threaded union where the tube transfers to metal. I would prefer not to have those hoses hanging free over the new headers and I am not sure where the air block off is needed.

Thanks again for posting this thread and any additional help.

-

01-13-2011, 12:32 PM #77Senior Member

- Join Date

- Apr 2008

- Location

- Madison, WI

- Posts

- 7,006

1999 Formula WS6 M6-sold- 2001 Silverado Z71

What you do is get a set of block off plates like this, bolt them to the manifolds or headers, and remove all the hoses/pipes for the AIR and EGR

-

01-13-2011, 01:49 PM #78

Thanks... after much research the past couple of hours I found out that 2002 models don't have an EGR (I got a little confused when I couldn't find it) so I just need to take out the air system and the new headers don't have EGR connections on them so I should be all good

-

01-13-2011, 05:24 PM #79

Did you get headers without the EGR and AIR connections? If you did you're okay, otherwise you'll need the block-off plates for the holes in the headers.

2000 Pontiac Firehawk #0041 of 742

2000 Pontiac Firehawk #0041 of 742

-

01-15-2011, 04:45 AM #80

The headers I bought have no EGR or AIR connection. I'm just waiting for a few small parts to come so I can put the headers and cut outs on. The anticipation is killing me I can't wait to hear my baby pur.

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

Install shop or DIY header install?

By dethinboots in forum External EngineReplies: 7Last Post: 09-24-2011, 06:35 PM -

Post LT header install header issues

By ob02z28 in forum External EngineReplies: 20Last Post: 02-18-2010, 04:10 PM -

header install so cal?

By sscamed in forum External EngineReplies: 0Last Post: 10-26-2008, 11:18 PM -

Header install, other

By Tide in forum GTOReplies: 0Last Post: 03-07-2007, 08:01 AM -

Header install

By linegtdt52 in forum Parts ReviewReplies: 9Last Post: 03-09-2006, 12:05 PM

Reply With Quote

Reply With Quote

Bookmarks