Results 1 to 20 of 24

-

01-12-2017, 05:25 PM #1Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

drag radials on a 10 bolt will it hold ?????

I have a 98 t/a with just a few bolt ons (lid, cat back and 3400 stall) if I put drag radials and it hooks will my rear end destroy itself. it has been regeared it has 3.73 moser ring and pinion on a 2 carrier. I see a lot of people on here running them and just want to be ready if I buy them. leaning towards nitto 555r but found some m/t that would fit the bill. just gonna be on street also no track at all.

-

01-13-2017, 07:08 AM #2Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

Depends on how hard you launch. But fair money is that it's not if but when you'll grenade it.

Auto you may be good for a while but I would start a new rear fund account.

Can't beat M/T, good tire.

Also if you do get slicks or radials the front tires also need to match type. Meaning if you run a bias drag slick the front needs to be bias, radial with radial. Mix the two and you'll have issues with the ride.

-

01-13-2017, 09:12 AM #3Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

Thanks for the input sir. I have my eye on a moser 12 bolt thinking probably this summer I'll be able to pull the trigger on it. Til then I guess m/t drag radials and a prayer every time I launch it.

-

01-13-2017, 09:29 AM #4Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

You also got another option. Hawks 3rd gen is making 8.8's now that are set up like mine. I fab'd mine 3 yrs ago and last yr they started making selling them because there were a quite a few of us building them on our own that interest got fairly big.

With an 8.8 you get almost just as strong as a 9" but less parasitic drag. The 8.8 has been a solid rear for a long time.

-

01-13-2017, 09:35 AM #5Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

Right on brother I'll look into them. Thanks again

-

01-14-2017, 04:40 AM #6

Some guys have had 10 bolts stay together while others have shattered... wheel hop at the line should be avoided at all costs with a 10 bolt.

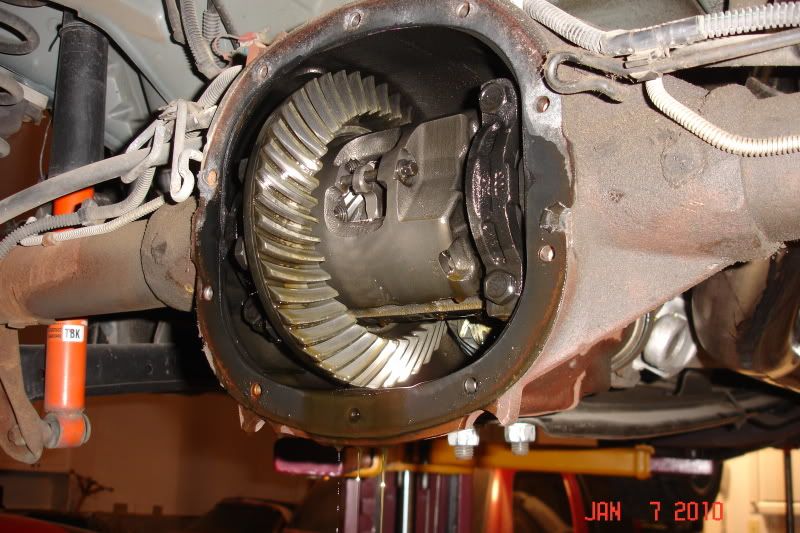

Here's the difference between the stock rear and a Moser 12 bolt:

Stock:

Moser 12 bolt:

I installed the 12 bolt back around 2010 and have been beating it at the track ever since. Couldn't bring myself to install a "Ford" part (ie. 9") in our Pontiac and the S60 was simply overkill with our A4, plus around 20 lbs. heavier.

-

01-15-2017, 02:50 PM #7Member

- Join Date

- Jun 2008

- Location

- Euclid,ohio

- Posts

- 197

Black- 1998 Z28

M6s' with drag radials,the little ten bolts don't last long at all. A4s' with drag radials typically don't abuse a little ten bolt.

Since you have a 98 that has an Auburn 'posi',the spider gears would break first.

As mentioned in an earlier post,wheel hop(whether with an M6 or A4) breaks parts. The biggest factor that allows wheel hop is the OEM shocks. I've seen even inexpensive KYB shocks reduce wheel hop. Whether or not you upgrade shocks,LCA relocation brackets help prevent wheel hop.Black 98Z A4 ,Yank SS3600 convertor,:SLP driveshaft loop,STB,PHB,LCAs,'flow-pac CAI,SFC,take-off 17x9 SS rims;StainlessWorks 'Y' & chambered exhaust,BMR LCA Relos,QA1s DblAdj-rear,Kenny Brown 6 Pt bolt-in cage,VGX pads

-

01-15-2017, 03:16 PM #8Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

I have never noticed wheel hop when I punch it its like I'm on ice with street tires. I put 260 lbs in the trunk and it was like 40 degrees so the roads were cold and it tried to bite a little but with an app I find that uses GPS my 60 ft times were like 3.8 to 5.2. I'm gonna try the lca brackets and some drag radials and see what happens. Thank for the input

-

01-15-2017, 04:43 PM #9Member

- Join Date

- Jun 2008

- Location

- Euclid,ohio

- Posts

- 197

Black- 1998 Z28

Of the two varieties(bolt-in and weld-in) of LCA re-los,the bolt-in variety will do,you can always get it welded later. Put them on ASAP so you can try them with your regular street tires.

Installation is no difficulty at all. Always do one side at a time to prevent the rear from shifting to a bad position. I've always done it with rearend up and supported and wheels/rotors off.

-

01-15-2017, 04:49 PM #10Member

- Join Date

- Jun 2008

- Location

- Euclid,ohio

- Posts

- 197

Black- 1998 Z28

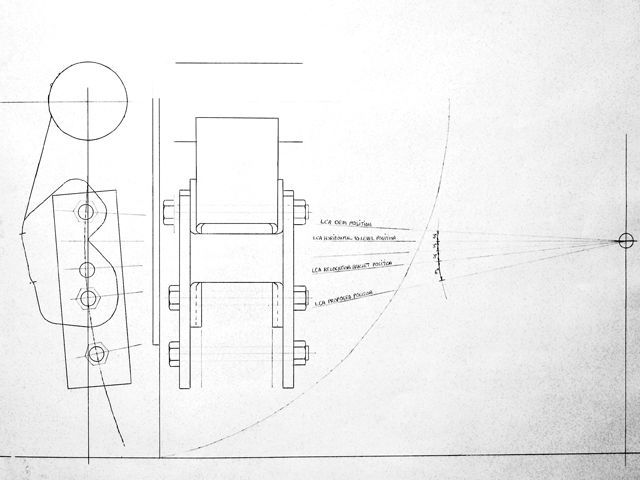

Here's something else I did a while back:

In January of 2005,installed BMR bolt-in LCA relocation brackets and launch traction immediately/dramatically improved.

I'm 'old school' of an era back to the original 'muscle car' of the mid to late 60s'. Back then,'lift bars' were used to enhance launch traction. The lift bars were used to take advantage of rearend housing rotation during acceleration. For every action,there is an equal opposite action. As acceleration,and/or start of acceleration occurs, and the inertia of trying to move the vehicle,from a stop,forward,sometimes as violently as possible like we like to do,the pinion wants to climb the ring gear and as it's trying,it's taking the 'snout' of the rearend upward too. this upward rotation tries to move anything below the centerline of the axles forward. In the 'old days',lower control arms on GM 'muscle cars' had the attaching point at the rearend housing lower than the attaching point at the frame. As the rotation of the housing occurred,it pushed the LCA forward,and since it was angled upward,it attempted to push the frame/body upward,and because of action/re-action,the rearend was pushed downward increasing traction. But because the angle of the LCA wasn't far from level,the upward push was small,but still traction enhancing. 'Lift Bars' were used to take that small upward push and change/convert it to a very definite and strong upward push.

Camaros,back in the day,had power and a beefy rearend. As time went on,with EPA regs,insurance,and gas shortages,power levels dropped and because a beefy rearend was no longer necessary because of low power levels,GM applied the little 7.5 10 bolt from another platform to the Camaros. As power levels increased in the 4th Gen,GM (I believe) angled the LCAs downward,from rear to front,thereby purposely decreasing traction to save the little rearend from breaking due to traction and not having to design in and supply a beefier rearend. That would also keep costs down to stay competitive in vehicle pricing.

LCA relos take the geometry back to 'old school'.

In March of 2005,I measured, dimensioned,and made a side view full scale drawing/layout of the rearend area.

the OEM LCAs are angled downward about 3 degrees,the relos change the angle to about 6 degrees upward (lowest relo hole),a change of 9 degrees. As you can see from the drawing,I made extensions (3 different versions). The further I lowered the LCA end,the better 'launch' traction was.

In June of 2005,I put these on.

Ran those until April of 2006 when I put these on

Ran those until April of 2008 when I put these on.

ran those until 2009,I'm currently not using any extensions,I got a totally different design in the works.

They worked well,better than I thought they would. As I changed design,traction increased.

The 'flaw' with the design was a flat tire would allow the extension to contact and scape on the ground. No,it didn't happen to me.

What started out as some 'testing' ended up as necessary when I put 4.56 gears in 2007.Last edited by pajeff02; 01-16-2017 at 02:10 AM. Reason: Link to Tech

-

01-15-2017, 04:57 PM #11Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

Good info thanks. That's what I had planned bolt ins for now and when I buy a 12 bolt or whatever I decide on I'll get the weld on with the new rear. Anything will definitely be an improvement like I said on dry pavement it is like ice when I floor it or even quick 1/2 throttle in 1st or 2nd.

-

01-16-2017, 09:56 AM #12

Drag radials don't really "hook" off the line. Even with a lot of suspension work done.

If you try launching at a high RPM, you're likely just going to spin still. Even so, it is still putting a lot of abuse into the drivetrain.

I used Nitto 555R's for several years and they were a decent tire that hooked well once the car got moving, but they were less than optimal for trying to get a jump off the line or any type of decent 60' time.Boost gets you laid, unless your name is Jon.

-

01-16-2017, 04:29 PM #13Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

Ya I'm not expecting a funny car take off by no means but spinning thru 1st 2nd and a little in 3rd then it kicks down to 2nd and sometimes starts spinning again. I have reasonable goals I would be happy with feathering and hook maybe half way thru 1st. Anything better than 100 ft of spinning is gonna be a plus.

-

01-16-2017, 05:03 PM #14Member

- Join Date

- Jun 2008

- Location

- Euclid,ohio

- Posts

- 197

Black- 1998 Z28

If drag radials don't hook,then why are so many able to lift the front end off ground using them. proper suspension and proper warm-up in the 'burn-out' box.

-

01-16-2017, 05:17 PM #15Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

I think he was referring to the street instead of the track. I think good street tires on my car at the track and it would be a completely different world.

-

01-16-2017, 09:25 PM #16

-

01-17-2017, 08:01 AM #17Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

I just proved that again this past weekend with my 555's. Great tire for street driving but at the track not so much.

My 60ft are horrible but once I'm getting traction I'm off like a freight train.

I either have to launch at low rpm's (2500) to get tracking or spin and quickly shift to 2nd to gain traction.

My 60ft are average 1.6-2.0 but my 1/8 mile times are avg 7.8 on street tires. My absolute best was 7.60 but that time I was on it in all, tree, shifting and launching.

-

02-21-2017, 09:01 PM #18Junior Member

- Join Date

- Jun 2008

- Location

- Butler mo

- Posts

- 80

Blue- 98 Trans Am

UPDATE: got a pair of m/t ss street drag radials and on the street the car dead hooks. No spin at all after a 3 second burn out to heat them up. I am very impressed. Been launching at around 2500 on a 3400 stall converter. So far haven't broke anything but time will tell.

-

11-29-2017, 04:30 PM #19Junior Member

- Join Date

- Nov 2017

- Location

- Maryland

- Posts

- 5

Blue- 2000 WS6 Trans Am

Hello, New member here.

If I can ask, I am a new owner of a 2000 WS6 Trans Am and the car was sold with 305/18 drag radials 555r and has the stock 10 bolt. Rear has 4.10's. I don't drag race it or do any clutch dumping but have shifted at higher rpm's on occasion. Is this still a concern for the rear. I was planning on replacing the rear tires with non drags but am not sure what to go with for some kind of traction. Rwhp is 412-425. Tires are rubbing on the outside sidewalls on road dips also.

-

11-29-2017, 04:44 PM #20

Stock power with stock tires is a concern for the POS 10 bolt.

Sent from my SM-G955U using Tapatalk

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

drag radials?

By bluonblk99 in forum General HelpReplies: 15Last Post: 05-06-2010, 05:59 PM -

How well does the 10 Bolt hold up?

By supersexy in forum DrivetrainReplies: 11Last Post: 09-04-2009, 08:41 AM -

need drag radials

By tomsws6 in forum Wheels and TiresReplies: 0Last Post: 06-29-2008, 04:58 AM -

WTB: M/T drag radials

By aquickfive0 in forum Parts Wanted / TradeReplies: 3Last Post: 05-02-2006, 09:13 AM -

? will my 10 bolt hold.

By skar in forum DrivetrainReplies: 16Last Post: 03-09-2006, 03:25 PM

Reply With Quote

Reply With Quote

Bookmarks