Results 41 to 60 of 240

Thread: My 8.8 Rear Build

-

05-30-2012, 01:38 PM #41

-

05-30-2012, 01:48 PM #42

Here is an example of a 33 spline non taper axle for a 12 bolt I'm currently building. Compare that to the tooth pic tapered axles out of my wifes car and you begin to see why larger axle tubes are also part of the deal,,,,,Since the larger axles take larger bearings. That's part of the reason anyway.

Last edited by Firebirdjones; 05-30-2012 at 01:52 PM.

-

05-30-2012, 02:26 PM #43

-

06-04-2012, 07:57 PM #44Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

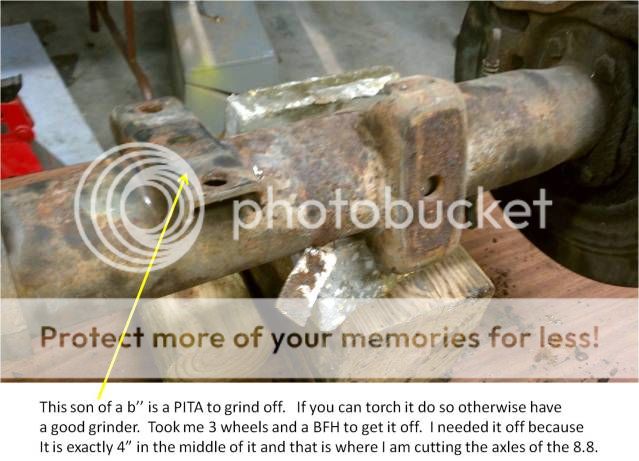

Machine shop called they now have the sleeve material and he said he should be done by Friday.

A little more then I thought it would be but I also having him clean up my cuts and remove the inside seem from the Ford rear.

-

06-08-2012, 06:25 AM #45Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

guess what I got back today.....

Here's a tease

I'll post better pics later...

-

06-09-2012, 07:22 AM #46Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

More pics

-

06-10-2012, 07:45 PM #47

Are you keeping a close tab on all of your total expenses, including your own time and labor for this project?

-

06-20-2012, 12:06 PM #48

-

06-24-2012, 08:45 AM #49

What i meant was why are you using a narrow 8.8 and not one from a CV where all you need to do is correct the length at the end AFTER you make all the attachment points permanent.

That brings other issues that you're going to have from multiple welds on each tube, which are going to move the tubes around which is what i asked how are you going to keep that from happening ?

-

06-24-2012, 04:50 PM #50

So you are going to wind up with little axles to fit the 7.5 axle tubes and small outer bearings,,,but have 31 splines on the carrier end???

Have you checked on that yet? I'm not even sure an axle company will recommend doing that and be liable at the same time. That sounds like it's going to be an odd shape. As small as the bearing end is on a 7.5, I'm not so sure you can fit a 31 spline count on there unless they taper the axle to a larger diameter on the inside, which is opposite of how tapered axles are made. You are going to have some weak links in this rear, axles being one of them. Not to mention it sounds like you are retaining C-clips in this build?

I don't have a 31 spline handy (they are in one of the cars) or I'd mic them for you and compare them to the spinely 7.5 4th gen axles I have laying in the floor here. I'm fairly certain the 31 spline mic quite a bit larger then a 7.5 axles does. Actually I posted a pic above comparing a 33 spline to the original 7.5 axles and the difference is huge.

Not trying to be a pecimist, but can't quite wrap my head around this whole deal. It's so much easier to do a 9 inch out of the boneyard, buy the 4th gen rearend brackets from Currie (they make torque arm brackets that attach to the 9" easily), narrow the tubes, cut and repline the original axles if on the cheap, or buy new (which ever you prefer) and you're in business. All the machine shop would have needed to do for you is cut the tubes, weld on new 9" ford bearing ends which actually retain the axles (so you get the benefit of c-clip elimination too) and cut and respline the original axles (9" ford axles are non taper so they can simply be cut any length and resplined for very little money)

-

06-25-2012, 06:48 AM #51Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

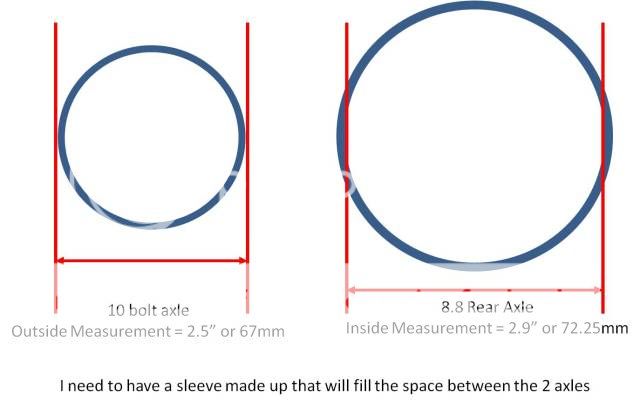

The 8.8 was one I got from a buddy that had one as a spare. Most guys use a 8.8 from a Mustang so they do not have to use sleeves but any 8.8 housing is usable. The axles from this 8.8 was almost 1 ft shorter then the 10 bolt.

I've pm both of you some of the links I'm using for this build. I would post here but they are from the other site and not sure if it's allowed.

I thought I answer the weld up for the tubes above - I plan on doing some plug welds to help prevent rolling.

C clips - I didn't post up my plans for that yet because I haven't gotten to that point in the build. I've been reading up on the elimination kit and are planning on do this.

As far as axles goes Moser makes custom axles for this build. You have to custom order and they go for about $380

We all know Spaz is currently running a 8.8 that is fab in this exact fashion. He's been running it since last Nov-Dec and has yet to break it. That says a lot to it's strength.

Many have made this and have had very successful efforts. I'm not building a 1000 HP, 9 sec track car but a solid street and occasional track use.

-

06-25-2012, 04:31 PM #52

Wow, 1 foot shorter?

I don't question the strength of the 8.8 itself, it's basically a ford copy of a GM 12 bolt. What raises a question for me is using the 7.5 axle tubes, which are smaller diameter, the axle bearing is very small, so you will have to make a custom axle to fit that small bearing. Since the axle diameter decreases for the 7.5 bearing, your 31 spline axles assentially won't be any stronger than the 28 spline 7.5 axles.

You will however gain a better made aftermarket axle with heat treating, so you gain some strength in that respect.

It's interesting, and I commend the effort put in. Not trying to take anything away from you.

-

06-25-2012, 04:35 PM #53Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

I also called Moser and they told me it's like you just said. The axle will be the same as a gm but with the ford 31 spline.

-

06-25-2012, 07:07 PM #54

That's what I figured, but you still wind up with a slightly stronger axle than a stocker because they'll use a better alloy and heat treat process.

-

06-25-2012, 07:11 PM #55Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

In a couple of the threads I sent you there are a couple guys on tech that are racing with the setup and haven't had a failure yet. I know anything can be broken but I hope all will work out.

-

06-25-2012, 07:29 PM #56

I'll have to check it out. I'm sure it will work. I don't doubt the 8.8's ability. When the rear first came out in the fox bodies in 86, around that time frame I had some buddies that were racing a few of these cars. Wasn't long before they were tickling bottom 10's (fast for that time) and doing it on the stock 8.8 (gear change of course). I've seen them dip into the 8's reliably now.

They are a glorified GM 12 bolt assentially. Off the top of my head here are some specs that look eerily similar

Ring gear dia on the 8.8 (8.8 inches hence the name)

Ring gear dia on the 12 bolt (8.875)

Pinion shaft dia on 8.8 (1.625/28 spline)

Pinion shaft dia on 12 bolt (1.625/30 spline)

Axle dia and spline count 8.8 (1.29"/28 spline) and (1.32"/31 spline)

Axle dia and spline count 12 bolt (1.28"/30 spline)

And the real biggy that shows how similar they are is the relationship between the ring and pinion or often called Hypoid offset. Something the 9 inch ford is known for having alot of (which is why is soaks HP)

Hypoid offset 8.8 (1.5")

Hypoid offset 12 bolt (1.5")

Now tell me Ford wasn't looking at the 12 bolt when they designed the 8.8 and I'll tell you I'm Santa Clause It's been a while since I've built an 8.8 but I seem to remember they even take the same crush sleeve and pinion bearings as the 12 bolt passenger car.

It's been a while since I've built an 8.8 but I seem to remember they even take the same crush sleeve and pinion bearings as the 12 bolt passenger car.

A funny thought that comes to my mind is how Ford kept the 28 and 31 spline counts in the 8.8, just like the 9 inch ford had been using since it's introduction. Guess they had to deviate from the 12 bolt at least a little bit to call it a ford rear,,,

-

06-25-2012, 07:38 PM #57Spaz is My Mentor

- Join Date

- Feb 2009

- Location

- Florida Man Status Acheivement

- Posts

- 11,759

Navy Blue Metallic- 98 T/A w/ mods, 00 FBVert

I read up on the c clip eliminators this afternoon after your question.

On the Moser site it told me you have 2 options: press on and weld on.

If I read the directions right the bracket (?) is pressed on to the axle by a 10 ton press to a set distance from the wheel hub. Next you cut an 1/8" off the end of the axle tube to make room for the bracket to get close enough to the housing flange in order to bolt on to it. Is this correct?

Where would you weld them then?

-

06-25-2012, 08:05 PM #58

That sounds correct. What you are reading are the instructions for the universal C-clip eliminator kit that is used on 10 and 12 bolts in general or the ford 8.8 in this case. You would use this on a stock axle tube, but you have to cut the small flange that stick out so the retainer plate can sit flush. Keep in mind once this is done the axle tubes can no longer be changed back to the original setup. The bearing is pressed on (like a 9" ford) after you slide on the retainer plate. That retainer plate bolts onto your 4 bolts that hold the backing plate. The axle is assentially retained by the press on bearing (which also uses a wedding ring behind it for added force).

The weld on axle retention I believe they are referring to is an actual 9" housing end that can be welded onto any axle tube, then you simply use the 9" ford method of axle retention (which is nearly the same thing) They make these with the GM brake bolt patterns so everything bolts together.

If need be I can dig up some pictures. I just finished building a 12 bolt for my wifes 4th gen. I Used 9" housing ends for axle retention (no C-clips).

-

06-27-2012, 09:23 PM #59

i need to see this to the end. to bad you arnt closer to me and i didnt see this sooner i could of cut up a set of sleves for you for the cost of beer and the scarp price of the stock

-

06-28-2012, 12:50 PM #60

Thread Information

Users Browsing this Thread

There are currently 1 users browsing this thread. (0 members and 1 guests)

Similar Threads

-

500CI Chevy LS1 Engine Build - How To Build A 500C

By Ed Blown Vert in forum Camaro / SSReplies: 0Last Post: 02-17-2009, 07:10 PM -

Possible rear end build

By chuckie669 in forum DrivetrainReplies: 9Last Post: 03-17-2008, 06:19 PM -

Rear alignment is off after Koni/!= rear isolator lowering, car pulls to right, specs

By anestech* in forum Suspension and HandlingReplies: 13Last Post: 07-08-2007, 09:42 AM -

Rear alignment issues after removing rear spring isolaters, adj trac bar fix it?

By anestech* in forum Suspension and HandlingReplies: 1Last Post: 06-19-2007, 07:06 PM -

Randy's Rear End Shop Get's Punked (Prank) - Woman looking for a bigger rear!

By powermelissa in forum Multimedia SectionReplies: 0Last Post: 05-25-2007, 10:37 AM

Reply With Quote

Reply With Quote

Bookmarks